In order to provide a wide range of products STW offers the

following thechinqeus.(if you would like to know what our machine

capacities are please contact us for our machine list).

Turning:

We are higlhy specialized in the technique of turning, including both simple and highly complex.

Most of our lathes are equipped with automatic leading featues.

Milling:

Processes include contouring, pocketing, thread milling, drilling, tapping and boring. These operations are carried out with a four or five axis machine therby avoiding defects by span.

Spark machining:

Using spark erosion machining of the form, material within the part is removed by an electrode. STW uses both EDM and wire EDM methodes.

Grinding:

Accurate and low surface roughness can be achieved by grinding the metal. Grinding requires craftsmanship accompanied by the correct tools.

Hardening:

Material properties can be changed or improves by heat treatment making them more workable, more resistant and stronger. There can also be disadvantages to this treatment so STW can help you in the selection of the right material suitable for heat treament.

Coating:

STW has developed serveral coatings that significantly improve the performance of tools and components. STW coatings are

extremely thin, harder than steel and reduce friction and wear.

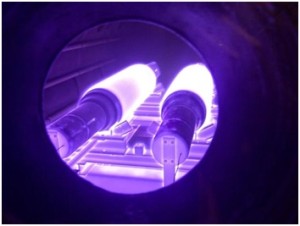

Plasma Nitriding:

In stort, plasma nitriding is a thermochemical surface treatment of steels including high alloy steel and stainless steel, resulting in a hard, wear resistant surface layer.

How it works

Plasma Nitriding creates a high voltage charge which triggers a chemicalreaction between the material surface and a reactive gas. The treated material acts as a cathode, ionizing the gas and

creating a plasma of nitrogen ions tha bombard the surface.

The nitrogen ions form nitredes with the elements of the material surface resulting in a hard clear surface layer.

No size change:

Plasma nitriding has the advantage that the curing process

can take place at temperatures ranging from 380 to 500 degrees

centigrade. The relatively low temperature treatments mean that virually no size change occurs.

The process is also suitable for high alloy steels.

Benefits of Plasma Nitriding:

• Improves the machanical properties of the base material.

• Low distortion and dimensional change: no regrinding and

necessary focus.

• High repeatability.

• Applicable for stainless steels while maintaining the corrosion

resistance.

• Alternative process for salt bath nitriding and kolstering.

• Smooter surfaces than other nitriding processes.

• Nitriding depths to 1 mm can often replace hardening.

• All steels can be treated.

• No salt residue makes post cleaning unnecessary.

• High toughness in the layered structure.

• Execellent polishability.

• High corrosion resistance, thus, no need for rustproofing

treatment such as galvanizing hard chrome plating,

phosphating ect.

• Low temperature.

Applications:

• Tools

• Dies

• Machine parts

• Engine parts including crankshafs, camshafts and piston rings